Failure to comply with the minimum legal standards for motorcycles can result in fines and penalty points, or even worse, the loss of your life.

Find out more about motorcycle tyre maintenance in this handy guide. Learn about motorcycle tread depth, tyre pressure and pillion passengers. Get answers to your frequently asked questions and find top tips to keep you safe on the road.

Why are tyres important?

Tyres are the only part of your motorcycle in contact with the road surface. Safety in acceleration, braking, steering and cornering all depend on this relatively small area of contact. It is therefore of paramount importance that motorcycle tyre maintenance is carried out regularly and that tyres are in a good condition at all times.

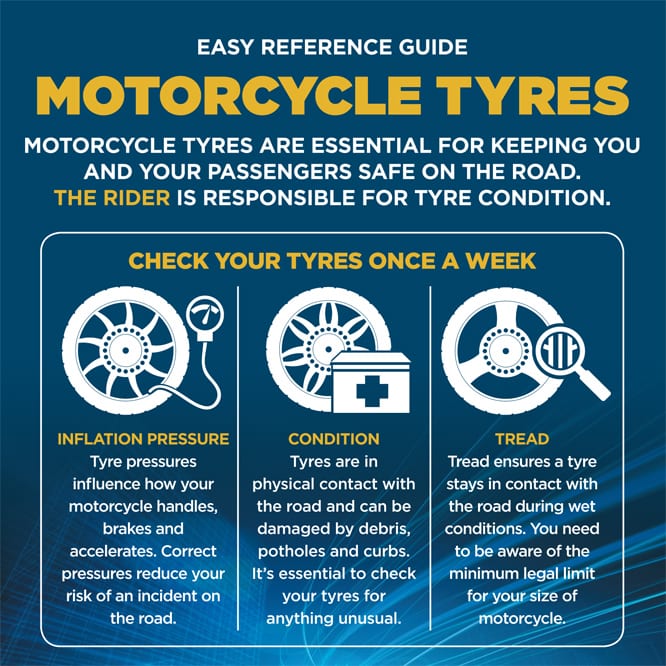

Motorcycle tyre maintenance

With the correct care and attention, your motorcycle tyres will help you to achieve maximum performance, enjoyment and safety without disruption and with minimal cost.

Motorcycle tread depth

You should check your motorcycle’s tread depth regularly.

The legal limit for motorcycle tread depth in the UK for motorcycles over 50cc is 1mm across ¾ of the tread pattern’s width, with visible tread on the remaining ¼. For motorcycles up to 50cc the law requires that all the grooves of the original tread pattern must be clearly visible.

But why is tread depth important? Tyre treads are designed to give good wet grip, but the road surface also plays a significant role in tyre to road adhesion. In general, wet grip decreases as tyre tread patterns wear down and as the depth of surface water increases. Riders should take this into consideration and reduce speed in wet conditions.

Motorcycle tyres normally have tread wear indicators in the tread grooves and as these are approached, you should consider replacement. Once the indicators are level with the tread surface the tyre should be replaced.

Motorcycle tyre pressure

You should regularly monitor your motorcycle’s tyre pressure as part of your motorcycle tyre maintenance checks. You’ll be able to find the recommended pressure for your tyres in your owner’s manual. But you can also check with the tyre manufacturer or a tyre specialist. If you own a classic or vintage motorcycle (pre-1960), you should reach out to the tyre manufacturer for more detailed advice as the pressure noted in the handbook may now be incorrect.

Under-inflating (or overloading) your tyres may cause rapid shoulder wear, excessive flexing and deterioration of the casing. While over-inflating your tyres may result in accelerated wear, reduced road contact, and an increased susceptibility to damage. Not only are both of these scenarios deeply unsafe, but they will increase your fuel consumption and make for a less comfortable ride.

Inflation pressures should be checked once a week when the tyres are cold using an accurate and reliable pressure gauge.

Don’t forget that you’ll need to adjust your vehicle’s tyre pressure depending on whether you are travelling solo or with a pillion passenger, check your owner’s manual to adjust your pressure appropriately.

Types of motorcycle tyre

Three basic tyre construction types exist for motorcycle tyres – radial ply, diagonal (cross) ply, and bias belted. Depending upon the wheel type, these may be tubeless (no tube required) or tube type (requiring an inner tube). It is recommended that tyres be fitted in matched pairs for optimum performance. (In certain European countries it is illegal to mix tyre brands on the same motorcycle. Local tyre regulations should be checked when taking your motorcycle abroad). Special tyres are available for sporting events, some of which are unsuitable for road use and are marked accordingly (normally NHS – Not for Highway Service).

How to choose motorcycle tyres

Modern motorcycles vary greatly in design and specification, ranging from scooter to all-terrain models, to suit a variety of purposes, including race, street, sport, touring, off-road and leisure activities. Tyres should be chosen with both the motorcycle and application in mind. For guidance, or if in doubt, you should: a) refer to the owner’s manual b) consult a tyre specialist c) use the tyre manufacturer’s fitment guidebook.

Tips for checking motorcycle tyres

- Check your tyre pressures from cold at least once a week using an accurate gauge

- Inflate tyres to the level recommended in the manufacturer’s handbook

- Inspect tyres for cuts, bulges, uneven wear or objects embedded into the tread pattern and replace if necessary

- Check that your tread depth is not below the legal minimum of 1mm (for motorcycles over 50cc)

- Use dust caps to keep dirt away from the valve core and to act as a secondary air seal

- If your rims are cracked or bent, they should be replaced immediately

- Check that your tread depth is not below the legal minimum of 1mm (for motorcycles over 50cc)

- Replace old or damaged valve stems

- Select the correct type of tyre for your machine and riding style

- Check that both tyres fitted to the motorcycle are made by the same manufacturer and have the same tread pattern

- Make sure that your tyre has been fitted the right way round by checking the directional arrows on the sidewall

- When replacing tube type tyres always use a new inner tube

- Make sure your tyre/wheel assembly is balanced correctly

- Keep oil and grease off your tyres using detergent if necessary

If you are unsure on any aspect of tyre pressure or tyre condition, take your motorcycle to an approved fitting centre and speak to a qualified professional.

Inspection and maintenance

Motorcyclists are strongly encouraged to be aware of their tyres’ visual condition such as tread depth, cracking of the tread or sidewall rubber, cuts or bulges, foreign objects, as well as being alert to any change in dynamic performance or behaviour such as air loss, noise or vibration.

Driving over potholes, kerbs and speed bumps, even at low speeds can result in the weakening or fracture of the tyre structure. Riders experiencing an in-service impact should ensure immediate inspection by a tyre professional. Lumps and bulges can indicate internal damage or a puncture and should be examined by a tyre specialist without delay.

Common FAQs

Tyre cracking is something that happens when the rubber on your tyre becomes hard and brittle and begins to break down. This can happen for a number of reasons.

Older tyres or those on vehicles that haven’t been driven for a while are more likely to crack, especially if they have been exposed to cool temperatures or left in uncovered storage.

Under-inflated tyres can also cause cracking, as under-inflated wheels cause more friction and as a result, more heat. Similarly, with the rubber stretched beyond what it recommended, over-inflated tyres can be susceptible to cracking.

Environmental conditions, such as extreme temperatures and prolonged wet conditions, can also contribute to tyre wear and tear. It is important to conduct regular motorcycle tyre maintenance to ensure you stay safe on the road.

Motorcycle tyres need to be ‘broken in’ to safely remove the thin film applied when they are demoulded in the manufacturing process.

For the first ~100 miles with your new motorcycle tyres, you should drive slower than normal, avoiding heavy braking, leaning or acceleration.

Long journeys on motorways can cause the meeting of the tyre’s sidewall and tread to ‘square-off’, which gives a feeling of loss of grip when the motorcycle is used on winding roads. Often on long journeys motorcyclists switch from the motorway to fast A- and B-roads, without knowing their motorcycle’s handling is compromised. The squaring-off phenomenon will always affect motorcycle tyres because of their design, but if the motorcycle is being constantly ridden on winding roads squaring-off will take longer to occur, meaning extended tyre life.

The type of journey covered isn’t the only reason for squaring-off, as other factors can have an impact. Most notably the compound of the tyre and the original profile of the tyre when new. Some tyres have a flatter profile to start with while others can be very pointy. The ‘pointier’ they start out as, the more the squaring-off will become apparent as the tyre gets older.

Tyre pressures can also affect the squaring, with both under- and over-inflation causing problems. If tyres are underinflated this will cause squaring off, as would running them overinflated, but then the width of the ‘squared band’ around the tyre would be narrower as the contact patch would be narrower in the first instance.

Tyre design means there is no cure for the squaring-off phenomenon, but once they’re aware it might happen, riders can adjust their riding accordingly. It’s important that motorcyclists make allowances for any unusual handling characteristics their motorcycle might show when they leave the motorway. Keeping tyre pressures at recommended levels is one way to ensure safe riding, as is rider awareness.

It is illegal and dangerous to mix tyres of different construction on motorcycles in certain ways.

If in doubt a tyre specialist should be consulted, but it is generally recommended that both tyres on a motorcycle should be of the same construction and from the same manufacturer.