The development of tyres over the past century has been stark, with multiple designs, structures, and sizes to accommodate a growing assortment of vehicles with different purposes. From tyres for electric vehicles and 4 x 4 tyres, through to van and motorcycle tyres.

However, the manufacturing process follows several steps:

- Blending

The rubber in your tyres comprises of over thirty different kinds of rubber, fillers, and other ingredients. These ingredients are combined in huge blenders to create a black compound that is then send on for milling.

- Milling

This is the formation of the basic tyre structure by cutting the cooled rubber into strips. Whilst this is happening other parts of the tyre are also coated in rubber and being prepared for assembly.

- Building

Tyres are made typically from the inside out. The steel belts, beads, ply, tread, textile elements and other components are placed in a specialist tyre-building machine. At this stage the components start to look like the beginnings of a tyre. The result is a ‘green tyre’.

- Curing

The curing process uses hot moulds to vulcanise the ‘green tyre’, bringing together all the components and giving the tyre its final shape. This includes the sidewall markings specific to the manufacturer and the tread pattern.

- Inspection

Most importantly, the finished product is thoroughly inspected by trained professionals who look for any blemishes or defects before it is shipped to be sold. Part of the inspection process takes a random selection of finished tyres and runs them through an x-ray machine to identify any weaknesses or faults.

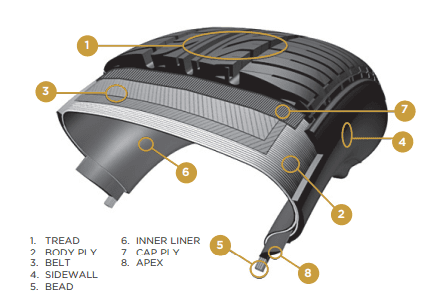

The parts of your tyre

There are many different elements that make up your tyre. They include:

Ply

Plies are the skeleton of your tyre made up of layers of fabric. Plies keep the tyre flexible but reduce elasticity and a made of rubber coated cords consisting of woven fibres. Carcass ply, laid directly above the tyre’s inner liner reinforces the strength of the tyre.

Beads

Beads form an airtight seal between the wheel rim and the tyre. They are rubber coated braided high strength steel.

Shoulder

The shoulder of your tyre is the small, bevelled edge between the tread and the side wall, and is integral to cornering.

Belt

The belt of a tyre is rubber-coated steek wires placed around the tyre. These reinforce the strength of the tyre whilst adding durability and extra puncture resistance.

Sipe and groove

The deep grooves in your tyre’s tread are designed to disperse water. The smaller grooves, called sipes, come into play during icy conditions.

Tread

Your tyre’s tread is crucial for grip and cushioning. You should check your tyre’s tread once a month and before long journeys. There is a simple way to do this using a 20p coin. The tread is where the rubber meets the road and will wear over time.

Rib

Ribs are used in some tyres and runs down the centre to reinforce weakest point of the tyre.

Drivers

Although all modern tyres are manufactured and inspected using incredible machinery and technology, drivers still have a hugely important part to play in ensuring tyres are maintained and checked regularly.